Analysis of Mixing in Bioreactors using Lattice Boltzmann Method

In the pharmaceutical and biopharmaceutical industries, stirred-tank reactors are extensively used for production of Active Pharmaceutical Ingredients (APIs). Characterization of the stirred-tank reactor and proper understanding of the mixing process is essential for streamlining the production of APIs. Computational Fluid Dynamics aid in the study of flow at any desired scale with a fraction of cost and shorter turnover time as compared to experiments.

In order to study the inherently turbulent, multi-phase, non-stationary flow characteristics of the mixing process, and to accurately predict the mixing time; efficient transient schemes are needed. We simulate a single-phase stirred-reactor by employing the Entropic Lattice Boltzmann Method (ELBM), amicable to moving boundaries. A major feature of ELBM is that it does not require any explicit turbulence modeling.

The model comprises a stirred tank of diameter 150 mm and fluid of height 1500 mm from the base of the tank. Four baffles of height 150 mm and thickness 15 mm are uniformly arranged along the walls of the tank. One Rushton impeller with 6 blades is placed at a height of 50 mm from the base. The angular velocity of the stirrer is 2672 rpm resulting in a Reynolds number of 23000. The results capture the flow at equal intervals of 20 times per rotation of the impeller in 4 vertical planes, each between a pair of baffles. The results presented are an azimuthal average of the 4 vertical planes, averaged over 15 rotations of the impeller.

Figure 1 shows two large circulation loops in the vessel. The upper circulation loop does not extend to the top of the tank indicating that the portion after this separation point, the fluid is not mixed well.

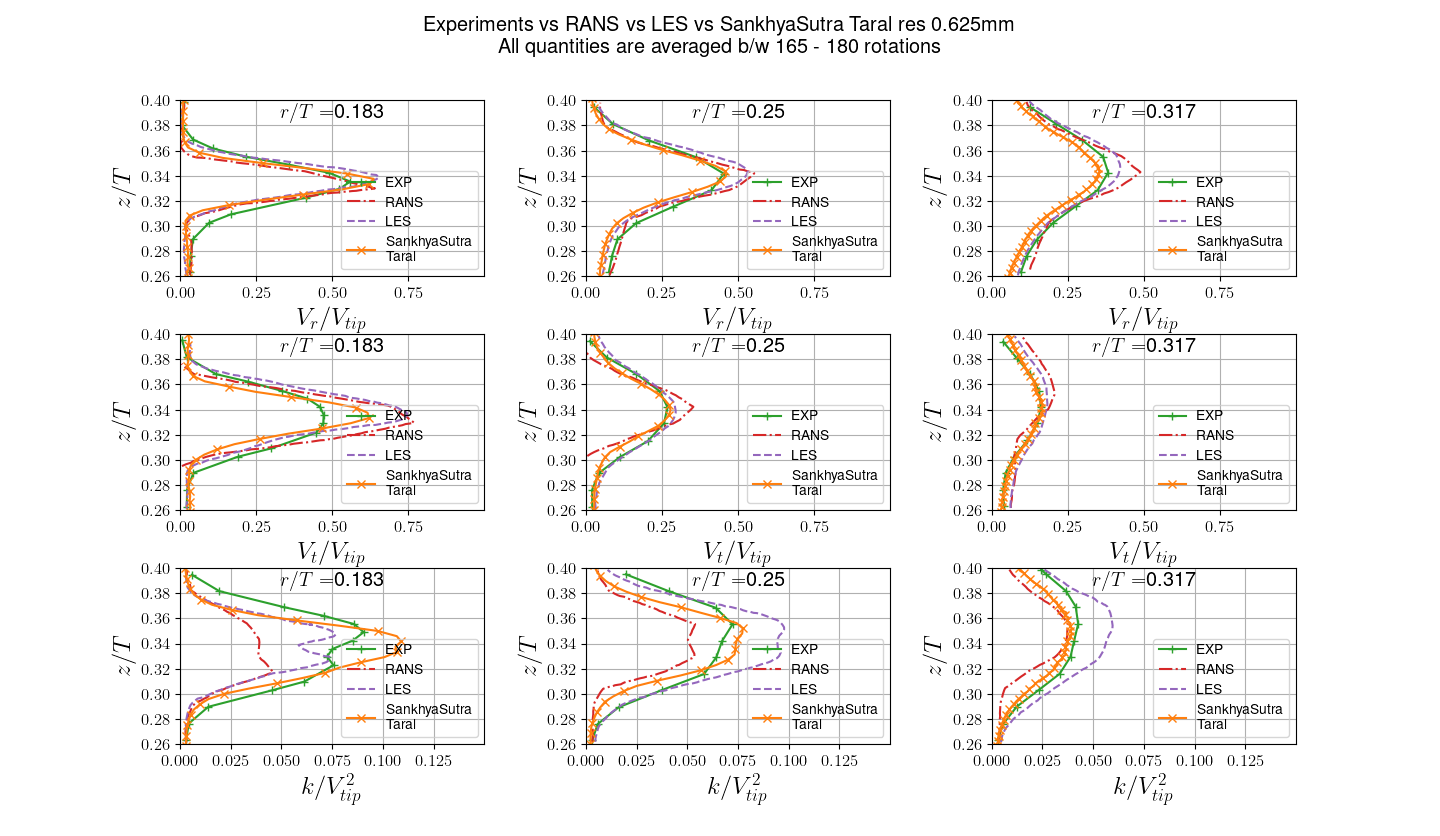

First-order quantities, like radial and tangential velocities, and second-order quantities, like turbulent kinetic energy, are plotted along the height of the tank at various radial positions in Figure 2. It can be noted that the SankhyaSutra Taral solver matches the experimental results closely. In comparison to RANS and LES approaches, the accuracy of SankhyaSutra Taral is most pronounced for prediction of turbulent kinetic energy.

This article highlights the accuracy for the results which can be achieved with SankhyaSutra Taral. Additionally, the inherent capability of ELBM towards scalability with increasing compute enables the user of the solver to easily move from lab scale to production scale analysis.

Further Reading: Adidela N et. al., Flow simulation of Bioreactors using Entropic Lattice Boltzmann method, AIChE Annual Meeting, Phoenix, 2022